The goal of our project is to reduce plastic pollution, allowing to recycle 3D printing waste for as many users as possible. So, we developed a rental-based circular model, allowing makers to basically use our product for only a few weeks, reducing their initial investment.

Title

Felfil As a Service

Company name

Felfil Srl

Country

Italy

Sector

3D Printing

Circular business model

Produce as a service

Product life extension

Challenge

The 3D printing market generates a significant amount of plastic waste, but private users often find recycling systems too expensive to be purchased directly. FELFIL identified two main barriers: the high upfront cost of recycling machines and the logistic complexity of sharing them. In addition, the lack of an accessible and legally robust rental model limited the spread of sustainable 3D printing technologies.

Solution

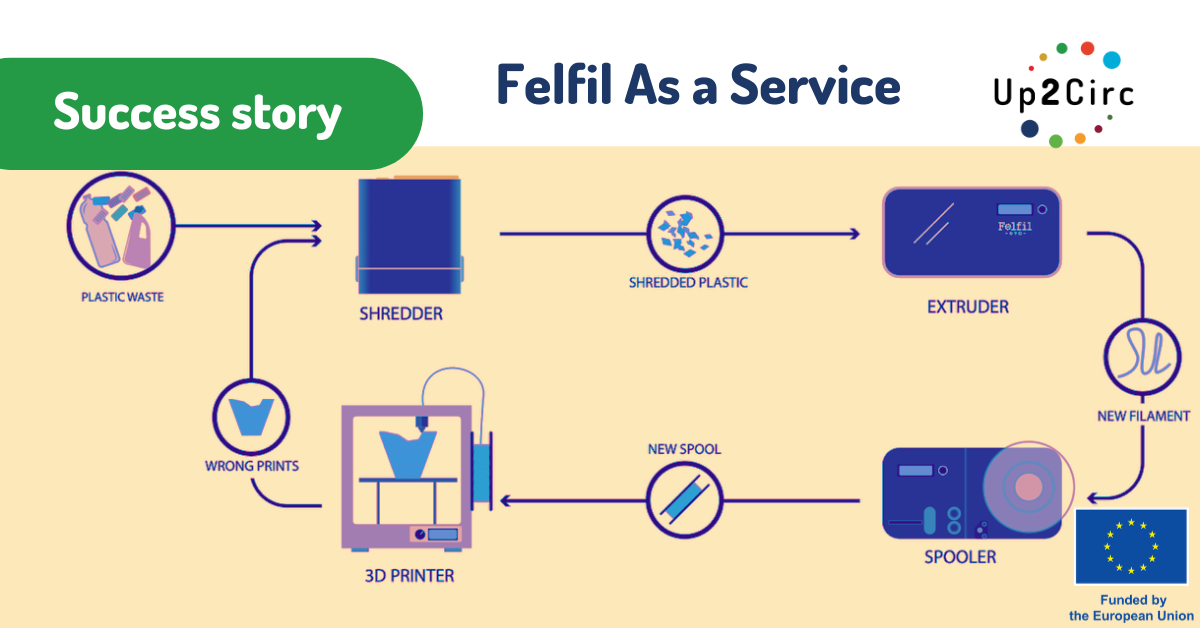

Felfil developed a short-term rental service for its 3D printing recycling systems, called Felfil as a Service (FaaS). The aim is to provide affordable access to plastic recycling at home. The project included: market analysis mainly made through surveys, the development of a reusable packaging, technical improvements to increase product robustness, the creation of a dedicated website, a pilot test with 5 units and the preparation of a draft rental agreement model.

Circular Economy Strategies/Business Model Implemented

· Rental model: shared use of machines among multiple users to reduce the number of units produced.

· Design for durability: technical upgrades to extend the product’s lifespan.

· Reusable packaging: minimized use of disposable materials for shipping.

· User engagement: surveys and community involvement to co-design the service.

· CO₂ reduction: LCA study showed up to 90% emissions reduction compared to the traditional model.

Impact

SDGs impacted: SDG 12 (Responsible Consumption and Production), SDG 13 (Climate Action).

The goal of our project is to reduce plastic pollution, allowing to recycle 3D printing waste for as many users as possible (SDG12). With this purpose we are going to monitor the amount of plastic that each consumer will recycle.

In the POC phase, 5 recycling units will be allocated for rental. The rental period has been set to 15 days, a time during which it is possible to recycle up to 15kg of material considering that the system takes 8 hours to recycle one kg of plastic. Considering the rental, delivery and repair time for each user, we consider that each recycling unit can reach 12 people/year, therefore one month per user. This would allow to reach 60 users over 90% reduction in terms of products manufactured.

Furthermore, we think the project could have a good impact for SDG13 goals too. Thanks to the EULA LCA software we calculated the Co2 produced during the entire life cycle of a Felfil recycling unit, whose duration is estimated in 10 years. The result is 420Kg of Co2 for the entire life cycle, equivalent to 42Kg/year. Co2 includes production, logistics, electricity necessary for use and disposal at the end of life. According to Kymia, a company that produces filaments for 3D printers, one of its 1 kg PETG spool emits 6.27 kg of Co2.

Key Takeaway

A circular business model can be economically viable for small companies when tailored to real market needs. Listening to the community, field testing, and a strong focus on environmental impact are key to innovation. The FaaS project demonstrates how circularity can be delivered as a service, not just as a product.