SECTOR

Broadcast and Film Lighting Equipment, High-value Content Creation

CHALLENGE

Kinotehnik faced the challenge of evaluating the feasibility of upcycling Practilite 602 and 604 LED lighting fixtures into next-generation models (Practilite 632/634). The objectives were to:

- Extend the product lifecycle and reduce environmental impact.

- Overcome barriers like high logistics and labor costs.

- Address customer and distributor reluctance to adopt an upcycling model.

Key difficulties included:

- Logistical complexity: High costs associated with long-distance shipping and labor-intensive refurbishment processes, especially in the U.S.

- Market resistance: Low customer and distributor interest in upcycled products due to perceived risks and lack of incentives.

- Limited awareness: Sustainability initiatives, such as upcycling, lacked visibility in the broadcast and film lighting market.

SOLUTION

Given the logistical and economic complexities of the initial plan, Kinotehnik adjusted its approach to focus on the following:

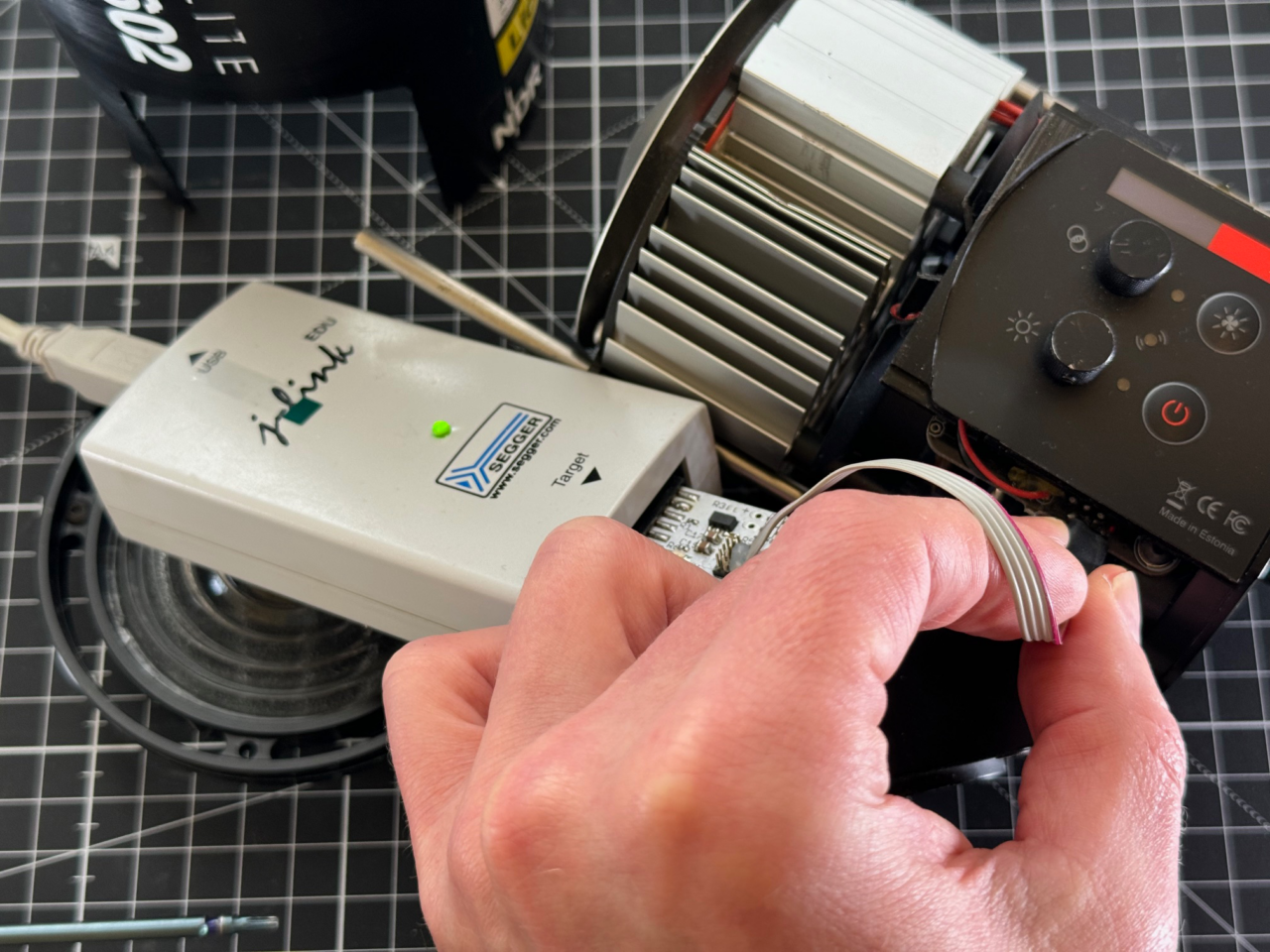

- Technical Validation: Practical testing confirmed that 75% of mechanical parts and 100% of electronic components could be reused without compromising quality.

- Routine Maintenance Upcycling: Instead of a standalone upcycling program, Kinotehnik integrated the process into routine maintenance cycles, allowing mechanical and electronics components to be refurbished or upgraded when customers send products for regular servicing. This approach minimizes logistical and labor costs while ensuring scalability.

CIRCULAR ECONOMY STRATEGIES/BUSINESS MODEL IMPLEMENTED

- Shifting focus: Kinotehnik transitioned from a broad upcycling initiative to a more practical approach integrating upcycling into routine maintenance.

- Resource reuse: The strategy relies on reusing 75% of mechanical components and almost 100% of PCBs, reducing the need for new materials.

- Localized refurbishment: Partnering with distributors to manage refurbishments locally, minimizing transport-related costs and environmental impact.

- Sustainability-driven customer incentives: Offering discounts and extended warranties to encourage customer adoption of upcycled solutions.

IMPACT

- Environmental Impact: Achieved a 25% reduction in CO2 emissions per fixture by reusing components and adopting localized refurbishment strategies, contributing to Responsible Consumption and Production plus Climate Action.

- Operational Insights: The feasibility study revealed that integrating upcycling into routine servicing significantly reduces logistical complexity and costs while ensuring continued product sustainability.

- Market Awareness: Highlighted the importance of targeted incentives and clear communication to improve customer and distributor participation in circular economy initiatives.

KEY TAKEAWAY

The initial upcycling program faced challenges due to high logistical and labor costs, but the feasibility study led to a viable Plan B approach: Integrating upcycling into routine maintenance. This strategy reduces costs, simplifies logistics, and aligns with circular economy principles, providing a scalable solution contributing to environmental sustainability.