COMPANY NAME

ALHOMNA SYSTEMS

COUNTRY

France

SECTOR

Energy

CIRCULAR BUSINESS MODEL

- Circular supply chain

- Product as a service

- Recovery and recycling

CHALLENGE

Sludge and digestate management is one of the most energy-intensive and carbon-heavy stages of wastewater treatment plants and anaerobic digestion facilities.

Public operational data (ADEME, ASTEE) identify sludge treatment, and especially thermal drying as the most energy-demanding post-treatment step, requiring several hundred kWh per tonne of dry matter and, in some configurations, representing a major share of site energy consumption.

In parallel, digestate from biogas plants remains highly diluted, leading to costly transport, high CO₂ emissions, and low nutrient concentration per transported tonne. These constraints highlight the need for low-carbon dehydration solutions able to drastically reduce water content, concentrate nutrients, recover water, and lower energy and transport footprints

SOLUTIONS

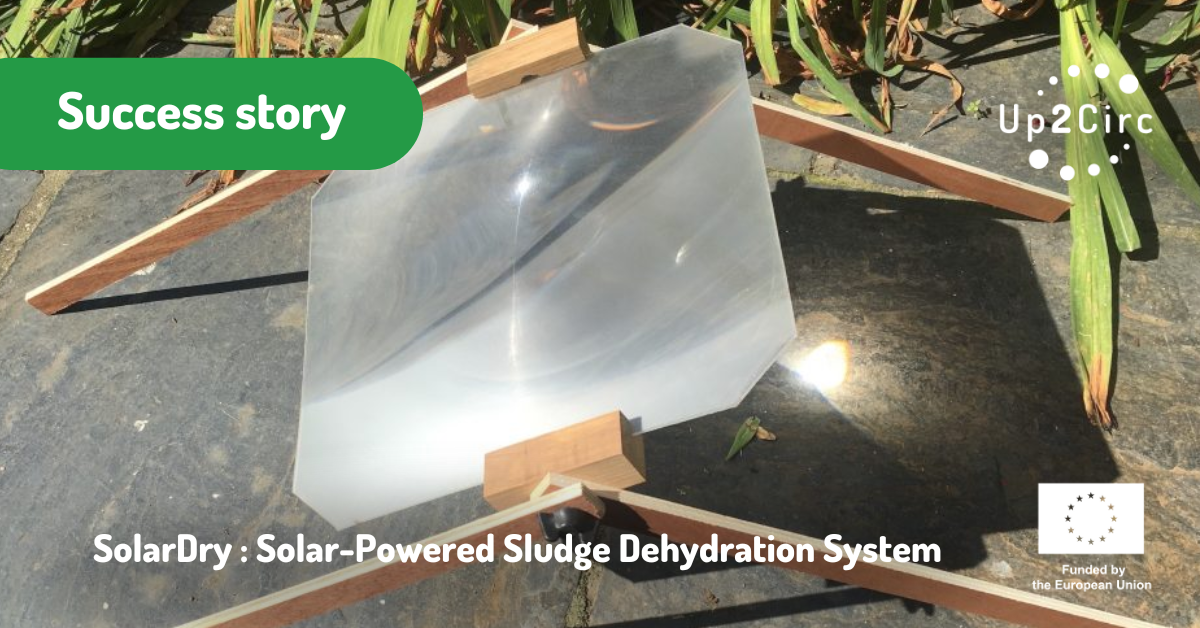

| SolarDry is a solar thermal drying system designed as a solar evapo-concentrator, combining the dehydration performance of industrial evaporators with the energy efficiency of concentrated solar power. Unlike conventional solar greenhouses used for sludge drying, which rely on passive air heating and are highly dependent on ambient temperatures — often requiring auxiliary heating (e.g. underfloor heating with heat pumps in winter) — SolarDry uses direct solar thermal concentration. Sludge or digestate is processed inside a closed tubular reactor positioned at the focal line of parabolic trough reflectors. The material is continuously mixed by a screw conveyor, ensuring homogeneous heating. Solar tracking concentrates heat directly into the reactor, evaporating water independently of external air temperature. The generated steam is recovered, passes through a turbine for energy valorisation, then condensed into reusable water, while dry matter is discharged at the end of the cycle. This configuration enables high dryness levels comparable to industrial evaporative concentrators, with a compact footprint, low auxiliary energy demand, and on-site deployment. |

CIRCULAR ECONOMY STRATEGIES/BUSINESS MODEL IMPLEMENTED

SolarDry applies a circular economy strategy focused on local resource recovery, material concentration and operational efficiency, following a combined “narrow and loop” approach.

By drastically reducing water content, the system limits sludge and digestate volumes, reducing transport needs and associated emissions while producing highly concentrated dry matter. After appropriate testing and validation, this dried material can be valorised as an organic fertilizer, used as a complement or alternative to chemically produced inputs, or blended with other natural streams such as compost or biochar to create marketable formulations.

Evaporated water is recovered, condensed and reused locally. Depending on quality requirements and validation, this water can be used for on-site cleaning operations, irrigation, or reintegrated into the wastewater treatment process, either upstream or within the treatment line, contributing to increased hydraulic performance (treated volumes) and improved resource efficiency.

From a business perspective, SolarDry enables decentralized, on-site treatment, transforming sludge and digestate from a disposal cost into a circular value stream, through flexible deployment models adapted to wastewater treatment plants, anaerobic digestion sites and agro-industrial facilities.

IMPACT

Environmental impact

Transport reduction: for the same amount of dry solids, increasing Dry Material from 21% → 60% reduces transported wet mass from 1.00 t to ~0.35 t, i.e. ~65% less mass to haul.

CO₂ from transport: using EU-certified truck emission intensities (VECTO), around 52 gCO₂ per tonne-km, this translates into ~3–4 kgCO₂ avoided per tonne of sludge per 100 km of transport (distance-dependent).

Water recovered: the same step (21% → 60% DM) corresponds to ~650 L of water removed and recovered per tonne of sludge treated (as condensate), enabling local reuse after validation.

Fertiliser substitution (working hypothesis)

At 60% dry matter, sludge processed with SolarDry concentrates most of its agronomic value in the solid fraction. Based on average nutrient contents reported in the literature (≈40–50 kg N/tDM and ≈25–35 kg P₂O₅/tDM) and conservative agronomic substitution coefficients, one tonne of dried sludge can substitute approximately 20–25 kg of mineral nitrogen and 20–30 kg of mineral phosphorus (as P₂O₅).

Considering published life-cycle reference values for mineral fertiliser production (~9.2–11.2 kgCO₂e per kg of mineral N, and ~1–3 kgCO₂e per kg of P₂O₅), this substitution represents an avoided impact of approximately 200–300 kgCO₂e per tonne of dried sludge produced by SolarDry, linked to avoided mineral fertiliser manufacturing, subject to nutrient analysis and regulatory compliance.

Economic impact

Logistics: ~65% less transported mass typically drives major reductions in transport costs and operational constraints (fewer trips / lower volumes).

Storage & flexibility: hygienised, stabilised dried matter becomes storable and easier to route to the best outlet (timing and logistics). Potential valorisation (work hypothesis): after regulatory compliance and quality testing, dried solids can be blended into formulations (e.g., with compost/biochar or high-potency organic additives) to support partial substitution of mineral fertilisers.

Mineral nitrogen fertiliser production has a high embedded footprint, with reference values reported in the order of several tCO₂e per tonne of nitrogen for common products.

Social impact

By producing a drier and hygienised material, SolarDry reduces odour emissions, handling constraints and sanitary exposure compared to wet sludge managed at ~21% dry matter. On-site dehydration significantly lowers transport volumes and truck traffic, contributing to reduced nuisance (noise, odours, congestion) for communities located near wastewater treatment plants and digestion facilities. Overall, SolarDry supports more acceptable, resilient and locally managed sludge treatment practices, subject to regulatory validation.

KEY TAKEAWAY

SolarDry demonstrates how solar thermal concentration can transform sludge and digestate management by reducing transport, energy use and emissions while turning a costly by-product into a concentrated, storable and potentially valuable resource. By combining proven evaporation principles with renewable energy, the project highlights a scalable pathway toward more efficient, circular and locally acceptable waste management systems.