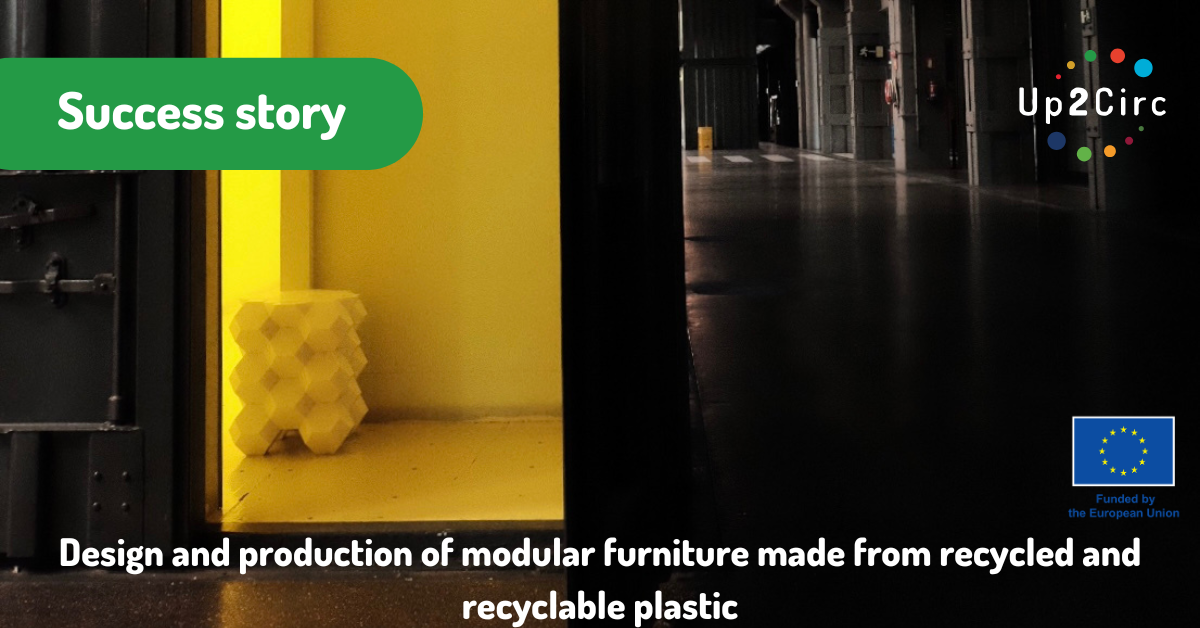

ATOM, a modular prototype that combines eco-design, local production, and digital co-design tools.

COMPANY NAME

UALOH

COUNTRY

SPAIN

SECTOR

Circular furniture & eco-design

CIRCULAR BUSINESS MODEL

Recovery and recycling

CHALLENGE

Plastic waste and the short lifespan of conventional furniture represent major environmental challenges. The project addresses the need to reduce virgin material extraction and improve waste management in the furniture industry by developing modular furniture that can be reused, repaired, and reintegrated into the production cycle. At the same time, it explores how circular models can promote inclusive employment and local manufacturing.

SOLUTION

UALOH developed a modular furniture system designed to extend product lifespan and enable easy reconfiguration, repair, and reuse. Each component can be disassembled and reassembled, reducing waste and facilitating material recovery.

The feasibility study led to the creation of a functional prototype and the design of a production model based on recycled and recyclable plastic, which will replace the PLA bioplastic used during testing in the next industrial phase.

To complement the product design, UALOH also developed the mock-up of a webbased platform that will enable customers and designers to co-create modular configurations and access circular services such as rental, resale, and return.

CIRCULAR ECONOMY STRATEGIES/BUSINESS MODEL IMPLEMENTED

UALOH’s business model is based on closing material loops and extending product lifespan through modular design, recycled materials, and local production.

- Narrowing the loop: The modular structure of the ATOM furniture line reduces material waste through optimised part geometry and efficient production processes. The transition from 3D printing to injection moulding with recycled and recyclable plastic will further improve resource and energy efficiency.

- Slowing the loop: Each product is designed for reconfiguration, repair, and reuse, allowing users to adapt furniture over time instead of replacing it.

- Closing the loop: The model includes a product recovery and resale system that enables circular return and reuse through a peer-to-peer marketplace.

- Regenerating the loop: Local production and collaboration with inclusive employment foundations ensure positive environmental and social impact in the value chain

IMPACT

Environmental impact

- Developed and tested a TRL 8 modular furniture prototype using PLA bioplastic, validating the design and assembly system.

- Defined key circularity KPIs, confirming the potential to replace virgin plastic with recycled materials and reduce CO₂ emissions by up to 79.68 tonnes/year.

- Ensured 100% renewable energy use during prototyping and advanced a localized production model to minimize transport emissions.

Economic impact

- Confirmed the technical and financial feasibility of scaling production through injection moulding.

- Developed a business and sustainability plan integrating circular strategies and resource efficiency.

- Validated market interest in modular, sustainable furniture through participation in innovation and circular economy events.

Social impact

- Established partnerships with inclusive organizations, including Fundación Juan XXIII, to integrate supported employment in future assembly.

- Strengthened local value chains through collaboration with nearby suppliers and production partners.

- Promoted awareness of circular design and responsible consumption through public presentations and events.

KEY TAKEAWAY

The Up2Circ project has enabled UALOH to validate the feasibility of its circular business model through the development of a functional prototype and the definition of a roadmap toward industrial production.

This process provided valuable insights into the technical, financial, and operational challenges of scaling circular design in the furniture sector.

It also reinforced the company’s commitment to combining environmental innovation with social inclusion, laying the foundation for sustainable growth and future industrial implementation.